PRODUCTS

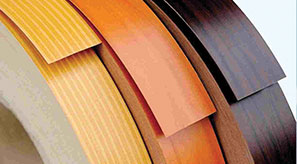

EDGE BAND

For decades in the furniture industry, edgebanding of wood-based panels has been an established practice with a variety of edgebands. The technological progress in engineering, the quality demands concerning visual appeal and also the almost unlimited diversity of materials to be processed are the factors represent special challenges for the modern adhesive technology. The quality of the edgebanding is becoming a key criterion for evaluating the quality of the entire furniture item in high-quality furniture manufacturing. The end customer demands a glueline that is hardly visible and perfect. Edgebanding is used to conceal the uncovered sides of wood materials such as plywood, particle board or MDF and increase the durability and give an appearance of a solid material. Edgebanding can be made of different materials including ABS, PVC, melamine, acrylic, wood or wood veneer. Common substitutes for edgebanding include face frames or molding. Traditional edgebanding was a manual process using ordinary carpentry tools and materials. In modern process, edge banding is applied to the substrate by an automated process using a hot-melt adhesive as ther high-volume and repetitive manufacturing of cabinet doors, wardrobes, Contemporary Plywood Furniture etc . Hot melt adhesives can be solvent or water based and may consist of various raw materials including EVA, PUR, PA, APOA, and PO. A substrate primer may also be used as a bonding agent between the substrate and the adhesive. Thicker edgebandings typically require a slight concavity to provide a tight and perfect glue line. The thickness can vary from .018 inches to 5mm or more. The machine that applies the edgebanding is called edgebander which bonds the edge with the substrate, trims the trailing and leading edges and top and bottom flush with the substrate, clear out any surplus and polish the finished edge.

HOT MELT ADHESIVE

Hot melt adhesive (HMA), additionally referred to as hot glue, could be a type of thermoplastic adhesive that's usually provided in solid cylindrical sticks of assorted diameters, designed to be molten in an electrical hot glue gun. The gun uses a continuous-duty component to soften the plastic glue, that the user pushes through the gun either with a mechanical trigger mechanism on the gun, or with direct finger pressure. The glue squeezed out of the heated nozzle is ab initio hot enough to burn and even blister skin. The glue is tacky once hot, and solidifies in a very few seconds to at least one minute. Hot melt adhesives can even be applied by dipping or spraying. In industrial use, hot melt adhesives offer many benefits over solvent-based adhesives. Volatile organic compounds square measure reduced or eliminated, and therefore the drying or hardening step is eliminated. Hot melt adhesives have long period of time and typically will be disposed of while not special precautions

GLUE (Synthetic Resin Adhesive)

Area of Usage

• All Types Of Woodworking & Labelling

• Packaging & Handicrafts

• Binding Books & Glass Fibers

• Paper Industry

• Textile Finishing, Etc.

• Toy Making

• High viscosity

• Non flammable

• Non toxic

• Environment Friendly

• Base: Poly Vinyl Acetate

• Appearance: White

• Viscosity: 15,000 – 19,000(By B.F. RVT Spl.-6, RPM – 20)

• pH: 4 to 6

• Specific Gravity: 1.02 to 1.05

• Flow: Continuous

• Spreadability: Smooth and easy

• Coverage: 3 to 3.30 Sq.m/ kg.(applied on both surfaces)

• Shelf Life: 12 months from date of manufacturing